TREATING TIPS

TIPS & REMINDERS

-

![Graphic with a checklist icon and text about treating season tip.]()

Order enough treatment for the amount of seed you’re treating. And order in advance so you’ll be ready to treat the minute your schedule allows.

-

![Illustration of a garage or shed with a treat container inside, accompanied by a text tip about treating season tips.]()

As you receive your treatment and inoculants this spring, make sure it's all being stored in optimal conditions for maximum viability.

· Store in a cool, dry place out of direct sunlight.

· Store in a temperature-controlled environment between 40-77 degrees F.

· Do not store outside, in a vehicle, or in an unheated shed (or hot shed in summer).

· Open when ready to use.

-

![Graphic with a green background, a thermostat and the text: TREATING SEASON TIP: Schedule regular heating system maintenance.]()

If you don’t have the proper calibrations set on your treater and pump stands before you begin treating, you could run the risk of overtreating or undertreating your seeds.

Too much treatment means less bang for your buck, while too little means less-effective results.

-

![An illustration of a horse's head with a close-up of its ears, along with text that reads: "Treating Season Tip: Ensure pump heads are closed when treating."]()

If they’re not, they can’t squeeze the line in that pump.

Open your pump heads at night to relieve pressure on the lines. Then close it the next morning. If you don’t close it, it will not pump treatment.

-

![A pixel art sprite of a guitar with a treat tip, accompanied by text that says "Treating Season Tip:"]()

Losing treatment flow? Pull your filter screen out and see if there is a blockage or gummed-up chemical.

Or maybe the lid was open on the tank and a bean got in and plugged the line.

-

![Illustration of rolling grass or waves with the text 'Treating Season Tip:' underneath.]()

Have a little inoculant trapped in your line at the end of a run?

Pour a little water in the tank to push the inoculant through—so you can use every last drop.

-

![Gauge showing low on treating season tip scale, with text indicating 'Treating season tip:']()

Switching from soybeans to wheat this summer? Bump down your treating speed.

UAS recommends 400 lbs/min. as a starting point for wheat.

FULLY AUTOMATED AT500: You can adjust the speed on the Utilities screen on your treater panel.

SEMI-AUTOMATED AT500: Knock your collar down a notch.

-

![Illustration of a container of winterizing compound with text that reads: Treating season tip: add winterizing compound to fuel tank to prevent fuel line freeze.]()

Once a month, shake the jugs for 2 minutes to prevent separation of chemicals. Use this product first when you start up next year.

-

![Treating Season Tips]()

Include what’s inside, the date it was pumped, and any special notes (e.g. “shake before use” or “use first next season”).

-

![Treating-Season-Tips]()

Especially if using an automated box scale. Don’t assume it’s correct from the last run.

-

![Treating Season Tips]()

Record product used, date, rate, weather conditions, and any issues or adjustments you made during each run.

-

![season-treating-tips]()

Flushing lines (especially with water after inoculant use) prevents buildup and clogs the next day.

-

![treating-season-tips]()

Old gaskets can cause leaking or pressure issues on your pump stands.

-

![treating-season-tips]()

Even small tweaks to your treatment mix can impact flow. Always double-check your rates.

-

![treating-season-tips]()

Don’t switch from a dusty seed to a clean one mid-calibration. Keep the consistency.

-

![treating season tips]()

Loose fittings are a top cause of leaks—especially on first use after storage.

-

![treating-season-tips]()

Even if you cleaned them last year, replacing or thoroughly cleaning your filters is a smart move.

-

![treating-season-tips]()

Keep backup element tubing, valves, gaskets, Quick Connects, filter screens, flowmeter

cables, etc. ready in case something goes down during a run.

-

![treating-season-tips]()

It catches drips and makes cleanup easier.

-

![treating-season-tips]()

Double-check your recipe math on treatment volume per cwt or unit.

-

![treating-season-tips]()

Use it for calibrations, rates, and conversion tools in the field.

HELPFUL ARTICLES ABOUT SEED TREATERS

-

![Agricultural seed treatment equipment in a warehouse with a green overlay text asking if seed treatment is a worthwhile investment.]()

Is a Seed Treater Worth the Investment?

-

![A large bulk seed system machine at an agricultural facility, with a conveyor and motors, labeled 'USC, LLC'.]()

Is a Bulk Seed System Worth the Investment?

-

![Industrial seed treater machine with a green sign above it that reads '5 Common FAQs on Buying a Seed Treater' in a warehouse setting.]()

5 Common FAQs on Buying a Seed Treater

-

![Indoor facility with large black seed containers, an industrial seed treating machine, and two workers in caps and work attire. The scene is related to seed treatment equipment.]()

5 More FAQs on Buying a Seed Treater

-

![Industrial equipment in a warehouse with a black banner overlay that reads "Common Bulk Seed System Issues & Fixes Troubleshooting Tips from UAS."]()

5 Common Bulk Seed System Issues & Fixes

-

![Industrial grains processing equipment with conveyor systems showing batch versus continuous flow comparison]()

Bulk Seed Systems: Batch vs. Continuous Flow

-

![Image of a seed treater machine with multiple black crates and a green banner with UAS logo at the top. Text reads: 'How a Box-to-Box Seed Treater Works'.]()

How a Box-to-Box Seed Treater Works

-

![A close-up of a metallic atomizer with a pipe attached inside a black container, with bold white text overlay reading 'Atomizers vs. Spray Nozzles']()

5 Ways Atomizers Trump Spray Nozzles

-

![Close-up of a digital scale head displaying -9.249 grams, connected to a wiring panel with colorful wires, in an electrical or laboratory setting, with instructional text overlay about calibrating a Cardinal 201 scale head on USC seed treaters and pump stands.]()

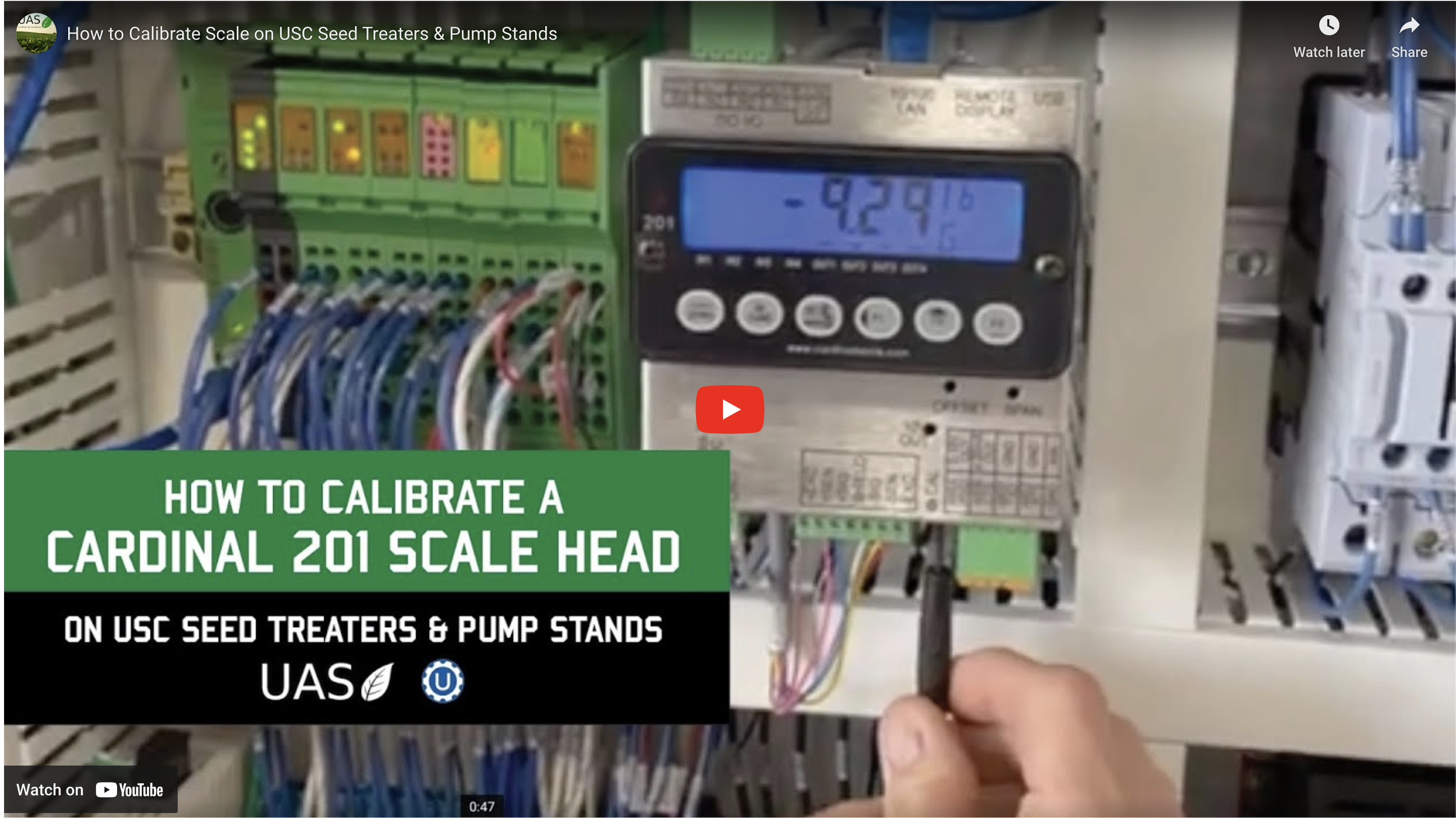

How to Calibrate a Cardinal 201 Scale Head

-

![A row of large white grain silos and a conveyor system beneath a clear blue sky. The image includes a promotional overlay for UAS, advertising equipment for bulk seed storage and handling.]()

The Best Equipment for Your Bulk Seed Site

-

![Image of a seed treater machine with green text above it reading 'Seed Treater' and 'Metering Options']()

Seed Treater Metering Options

-

![Illustration of gardening tools and tips for treating season, including a soil probe, water filter, and fertilizer container, with text 'Treating Season Tips' and a leaf symbol.]()

Simple Treating Tips

-

![Close-up image of a used septic tank lid with a warning message about buying used treaters at auction.]()

Be Cautious When Buying Used Treaters on Auction Sites

-

![Indoor agricultural facility with large seed planting machinery, including conveyor systems and storage bins, and a person working nearby.]()

When Is the Right Time to Upgrade to a Bulk Seed System?

-

![People in a workshop observing an industrial steel auger conveyor machine.]()

Flighting: Why Poly Augers Trump Steel and Conveyors

-

![Large industrial drum treating machine inside a warehouse with metal walls and small windows, labeled with UAS LLC branding.]()

5 Perks of Drum Treaters

-

![A seed treater machine dispensing seeds into large black and white containers inside a building with metal walls. Text on the image reads, 'Who uses a seed treater?']()

5 Types of People Who Use Seed Treaters

-

![A close-up of a seed treating machine releasing red seed pellets into a container with the text '5 Benefits of Box-to-Box Seed Treating' overlaid.]()

5 Benefits of Box-to-Box Seed Treating

In addition to killing nematodes, BioST Nematicide has proven to work against Corn Rootworm (CRW) too.

HELPFUL ARTICLES ABOUT SOYBEAN SEED TREATMENT

-

![Close-up of a seed sprouting from soil with a green and black overlay text about seed treatment, fungicides, and insecticides.]()

Understanding Seed Treatment

-

![Close-up of green leaves with sunlight shining through, alongside text that reads 'How to choose a seed treatment blend UAS' with a small leaf icon.]()

How to Choose a Seed Treatment Blend

-

![Cover page of a guide titled 'Common Diseases in Soybeans and How to Fight Them' with images of various soybean plant diseases.]()

Common Soybean Diseases & How to Fight Them

-

![Close-up of pink and green container labeled UAS with a leaf logo, and overlay text reading 'The Benefits of Stocking Up on Seed Treatment'.]()

The Benefits of Stocking Up on Treatment

-

![Close-up image of three ladybugs on a dark surface with overlaid text: 'Combat Corn Rootworm with BioST Nematicide' and the UAS logo with a leaf icon.]()

Combat Corn Rootworm with Nematicide

-

![Close-up of soybean leaves with yellow and brown spots, indicating disease, overlaid with the text 'Managing Sudden Death Syndrome in Soybeans'.]()

Managing Sudden Death Syndrome in Soybeans

-

![Close-up of a soybean plant with fuzzy pods, with a banner about soybean disease management and minimizing soybean yield loss from white mold, featuring UAS logo.]()

Minimize Soybean Yield Loss from White Mold

-

![Red granular fertilizer being poured from a dispenser into a plastic container.]()

Ace™ 3.8L ST Fungicide

-

![Dry soybeans with fungal disease on soil]()

Fungicide Efficacy on Soybean Diseases

-

![A green field of crops at sunset with text overlay introducing Legend™ SL St Insecticide by UAS.]()

Legend™ 5L ST Insecticide

-

![Hand holding pink seeds with a black text box on top that says 'Introducing Anchor™ 3L ST Fungicide' and UAS logo with a leaf icon.]()

Introducing Anchor™ Fungicide

-

![Two white plastic bottles with handles and screw-on caps placed on a concrete floor, with a sign that reads 'UAS How to store leftover seed treatment'.]()

How to Store Seed Treatment

SEED TREATING PREP CHECKLIST

Before you spring into action during seed-treating season, take some time to prepare your equipment and chemical supply. Order any chemistry several weeks before you plan on treating, and get your treaters and equipment ready by downloading our treating season prep checklist.

SEED TREATER WINTERIZATION CHECKLIST

After treating season winds down, it’s important to winterize your treaters, pump stands and other treating equipment so it’s spic, span and ready to roll for next season. Not only will some simple cleaning and care keep your equipment in tiptop shape, it’ll extend the life of it and prevent costly and time-consuming repairs down the road. Download our winterization checklist to ensure everything is cleaned and stored properly.