5 Things to Winterize After Treating

It’s not even summer yet, but we’re already talking about winterization. Once you’re done treating this year—which many of you likely are—it’s important to winterize your treaters, pump stands and other equipment so they’re spic, span and ready to roll for next season.

Not only will some simple cleaning and care keep your equipment in tiptop shape, it’ll extend the life of it and prevent costly and time-consuming repairs down the road.

Before you store away your treating equipment, follow the steps outlined below for each piece of treating equipment. Or, click the button below to download and print them off.

To save space, pump any remainder product into 2.5-gallon jugs.

Once a month, shake the jugs for 2 minutes to prevent separation of chemicals.

Use this product first when you start up next year.

Store all leftover product in a climate-controlled environment (between 35-90° F).

On your treater…

Slide out the atomizer, then clean with a putty knife and warm water (Simple Green works great too).

For box-to-box treaters, ensure the poly-cupped auger is cleaned.

Open the access door at the base of the auger, clean out any residual seeds/treatment.

For drum treaters, ensure the drum is cleaned. Wipe down residual treatment inside the drum.

Locate any grease points on the unit… then grease them up.

On your pump stands…

Use warm water and a cleaning agent (Simple Green again) to flush out your lines.

Recirculate the pumps with the solution to ensure everything is cleaned out.

This may need to be done a few times.

Run the treater with this solution. Run it through the IP pumps, atomizer, flowmeters and chemical tree.

Once the lines are cleaned out, run antifreeze through all of them. This will prevent any cracking due to freezing over the winter months.

Replace any worn tubing. IP pumps utilize peristaltic tubing (squeeze tubes) that may need to be replaced.

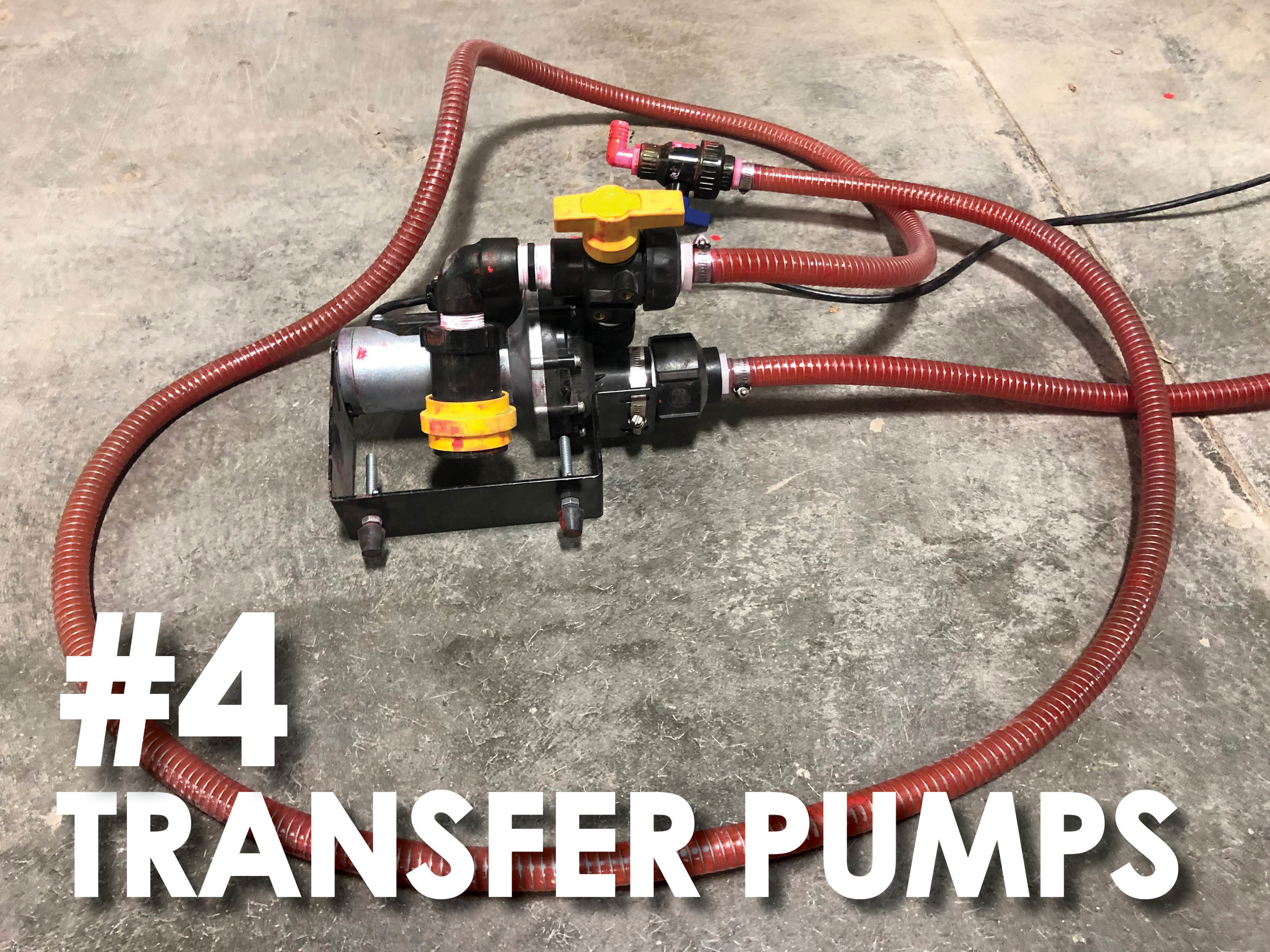

For your transfer pump…

Pump water through the transfer pump.

To do so, place the micro-matic fitting (keg fitting) in a 5-gallon bucket of water and turn the pump on.

This may need to be done a few times.

Catch your waste water in an empty keg or bucket.

Once the lines are cleaned out, run RV antifreeze through them as well.

On your conveyors…

At the base of your conveyors, clean out any residual beans/corn/wheat.

Track and tension the conveyor belts if needed.

Grease the bearings.

This short list is sure to uphold your equipment’s long-term performance. For any more questions, just give us a call at 888-402-4787.